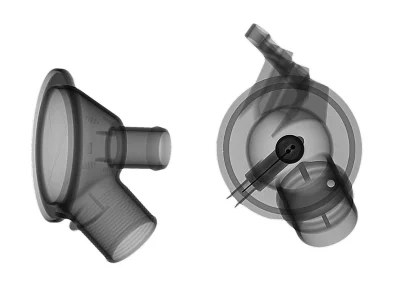

TruView™ 160

Primarily utilized for non-destructive testing across a wide range of applications, including metal castings, hardware components, plastic products, refractory and resin materials, review samples, ceramic bodies, and welded metal parts. The system is especially suited for inspecting small and micro-sized products with precision and reliability.

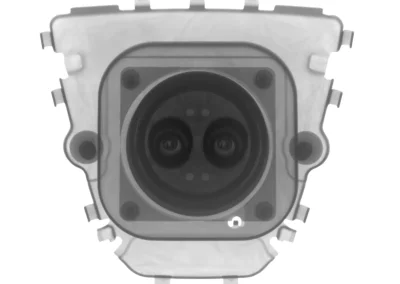

TruView™ 160 XL

Widely utilized for the inspection of small to medium-sized products, including metal castings, welded components, hardware, plastics, rubber, refractory and resin materials, composite structures, and ceramic bodies. The system serves a broad range of industries such as equipment manufacturing, electronics, automotive, and high-speed rail, delivering reliable non-destructive testing solutions with precision and efficiency.

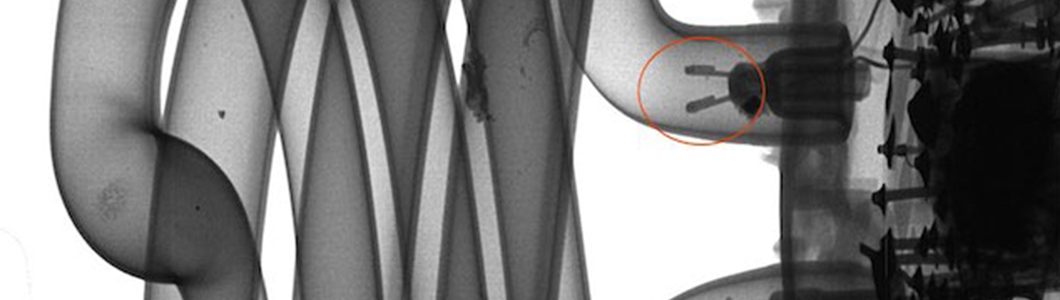

TruView™ 450

Engineered for non-destructive testing (NDT) of aluminum castings, ductile iron, and automotive components. The system accurately detects porosity, gas bubbles, and foreign material inclusions, ensuring product quality and reliability.